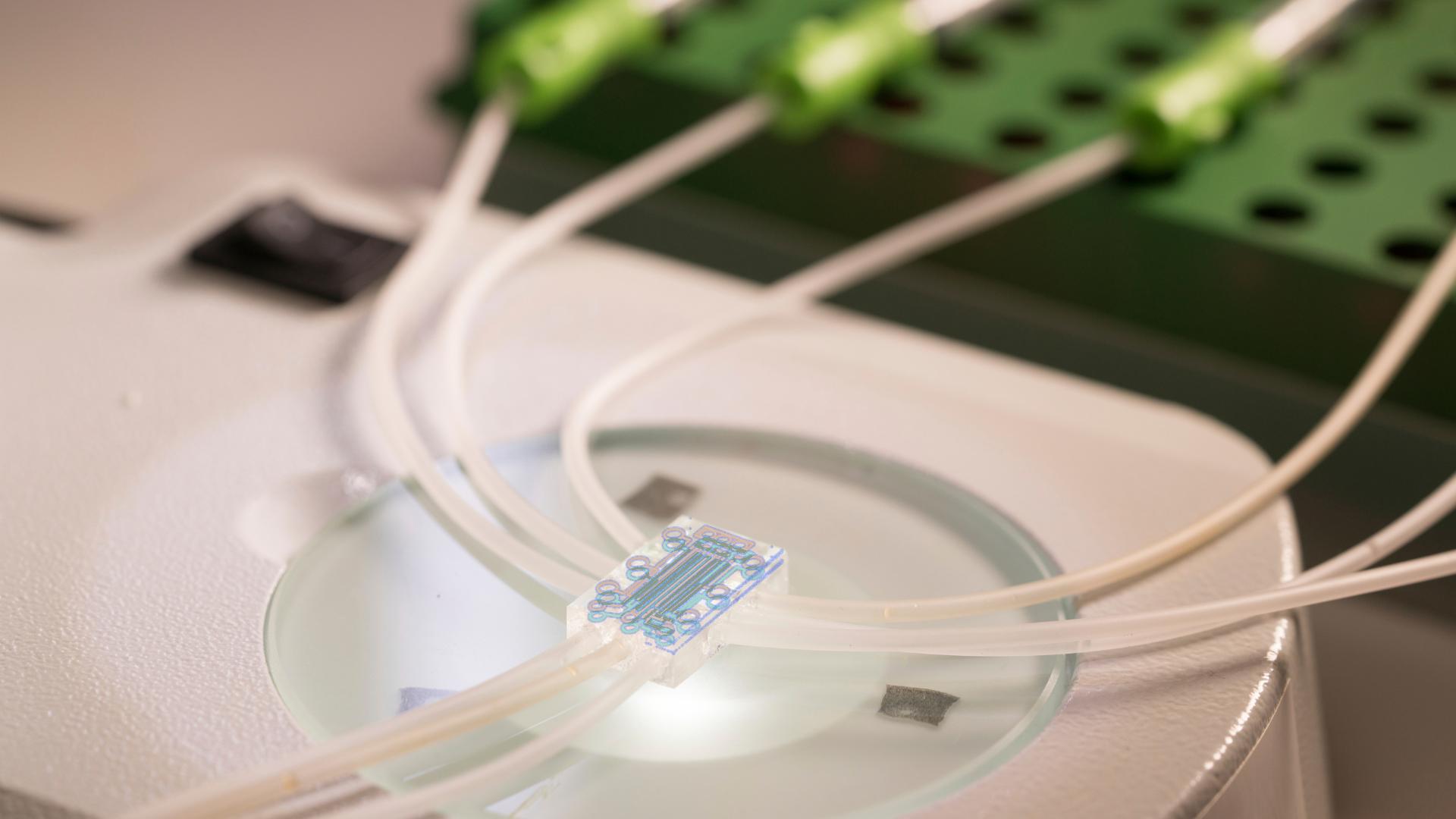

Microfluidics is the technology that can precisely process and manipulate tiny fluids with volumes ranging from 10−9 to 10−18 L in microchannels to make very uniform (i.e., monodisperse) droplets. Our team are currently working on the use of this technology in the precise delivery of drugs and active ingredients. We aim to produce NDDSs for veterinary medicine. NDDSs are pharmaceutical formulations with a particle size of 10–1000 nm, consisting of drugs and functional drug nanocarriers prepared from biocompatible and/or biodegradable materials. They can deliver drugs to the desired site and realize the drugs’ sustained release, thereby reducing drugs’ toxicity and improving drugs’ bioavailability. We are currently using various NDDSs, such such as liposomes, nanoparticles, and micelles. Usually, NDDSs are prepared by bulk methods including, but not limited to, homogenization, self-assembly, and nanoprecipitation. These traditional methods result in wide particle size distribution, poor dispersion, and high batch-to-batch variations in physicochemical properties, mainly owing to low mixing efficiency and slow mass transfer. Microfluidics on the other hand offers a new innovative strategy for fabricating NDDSs. It can precisely process and manipulate tiny fluids in the microchannel, resulting in some features including small volume, large specific surface area, and fast mass and heat transfer, which brings about remarkable advantages such as low consumption of reagents, fast mixing, and precise control of the physicochemical properties of NDDSs.